IT Equipment

Leak Detection Solution for AI Servers

Micro-Fluidwatch is a compact, all-in-one leak detection system combining a highly responsive sensor cable and controller. Designed for data centers and IT equipment, its flexible cable quickly detects the presence of any liquid within seconds. With no exposed metal components, it ensures long-term reliability and seamless integration into demanding environments.

Key Features:

Detects both electrically conductive and non-conductive liquids (i.e. PG25 and dielectric fluids)

V-0 flame retardant construction

Insensitive to dust dirt buildup and corrosive environments

Miniature form factor fits hard-to-access areas

Highly flexible sensing cable

LED status indication

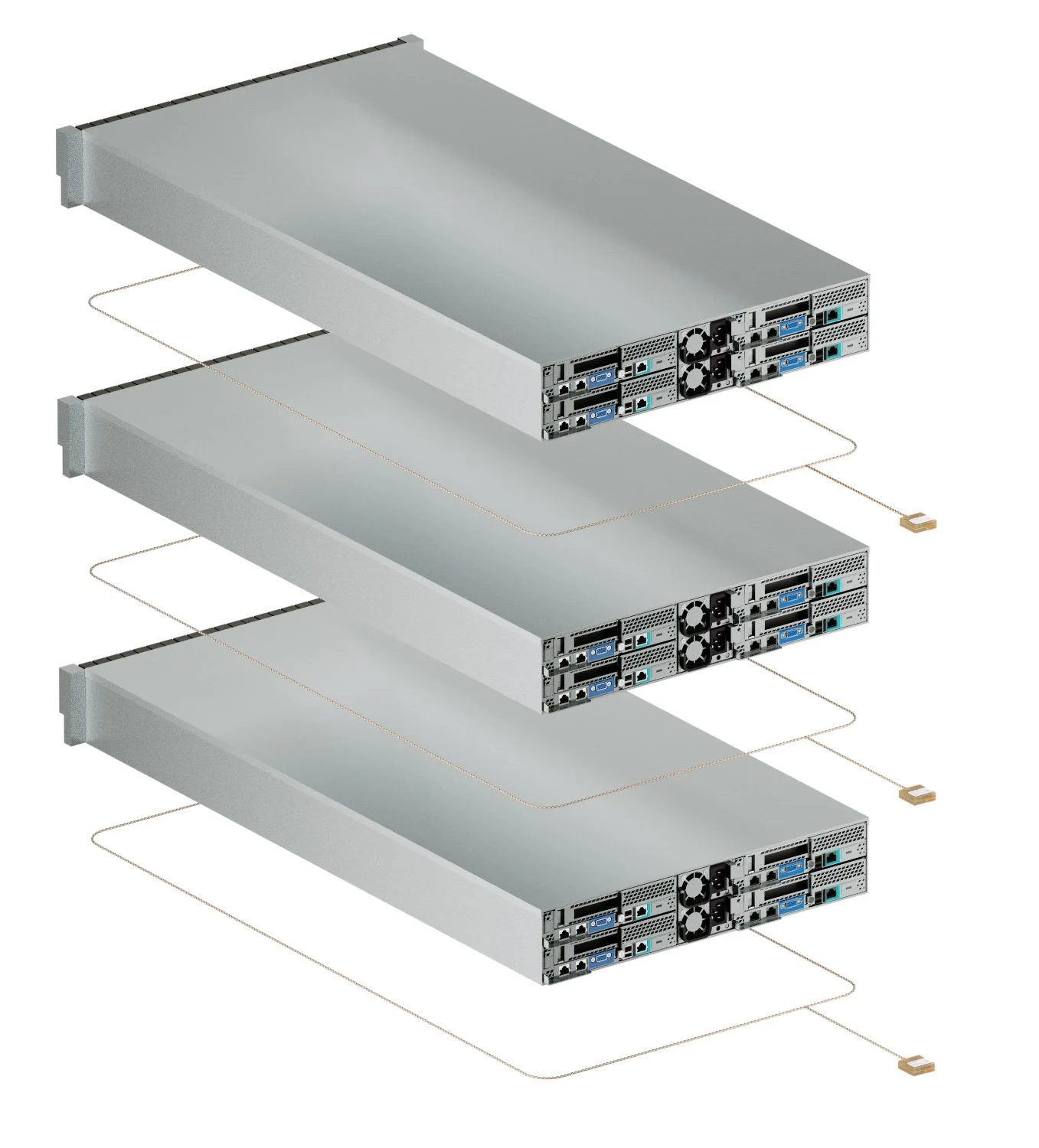

Micro-FluidWatch integrated into server rack setup (as shown).